In the global trade of industrial minerals and metallurgical feedstocks, a single question stands above all others for a buyer: “How can I be certain that the product I receive is the exact quality and specification I paid for?”

While suppliers can provide internal lab reports and data sheets, the gold standard for trust and risk mitigation comes from independent, third-party verification. This is where SGS, the world’s leading inspection and certification company, plays a critical role. This article explains what SGS verification is and why it should be a non-negotiable part of your procurement process.

What is SGS?

SGS (formerly Société Générale de Surveillance) is a Swiss multinational company recognized globally as the benchmark for quality and integrity. They are a neutral third party with no financial interest in the transaction between a buyer and a seller. Their role is to independently inspect, verify, test, and certify that a commodity meets the agreed-upon standards.

A Simplified Look at the SGS Inspection Process for Minerals

When Kaolin.om engages SGS for a shipment of iron ore or chrome ore, a standardized, rigorous process is followed to ensure objectivity:

- On-Site Sampling: An SGS inspector physically travels to the location of the cargo (e.g., a port stockpile). Following strict international protocols like ISO standards, they collect multiple samples from different points of the pile to create a representative cross-section of the entire lot.

- Sample Preparation: The collected samples are then securely transported to a workshop where they are mixed, crushed, and divided according to standard procedures. This creates a final, homogenous composite sample that accurately reflects the quality of the entire shipment.

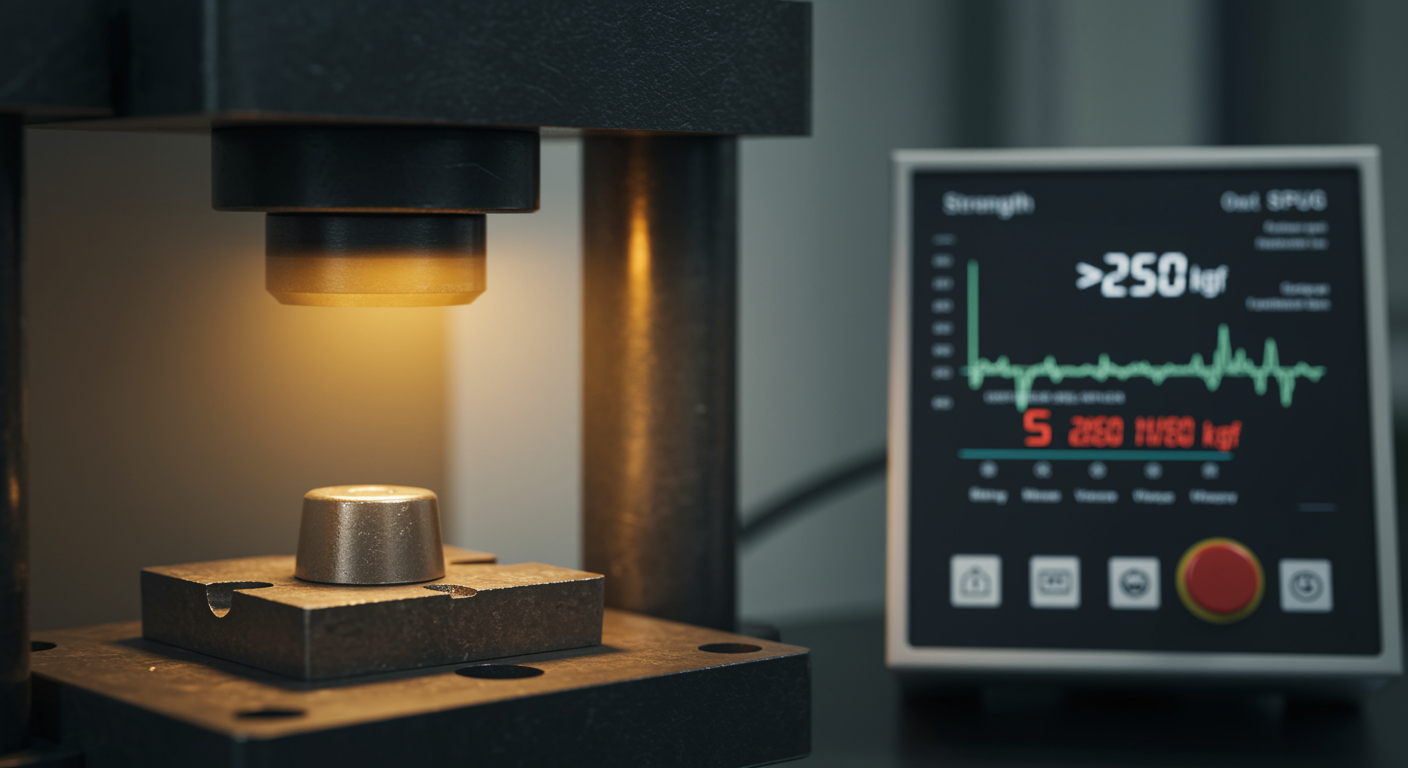

- Independent Laboratory Analysis: The prepared sample is sent to a laboratory for detailed chemical and physical testing. This analysis determines the exact specifications, such as the total Iron (Fe) content, the Chrome Oxide (Cr₂O₃) percentage, impurity levels, moisture content, and particle size.

- Formal Reporting: SGS compiles all the data into an official, internationally recognized report. This document is not an opinion; it is a factual, data-driven snapshot of the cargo’s quality at the time of inspection.

The Key Benefits of SGS Verification for You, The Buyer

For a procurement manager or technical director, an SGS report provides three essential layers of security:

- Risk Mitigation: The primary benefit is mitigating the risk of receiving off-spec material that could disrupt your production, damage equipment, or result in a lower-quality final product. The SGS report verifies the quality before the transaction is finalized.

- Objective Quality Guarantee: It replaces a supplier’s promise of quality with independent, undeniable proof. You are no longer just taking the seller’s word for it; you have a data sheet from the world’s most trusted name in inspection.

- Financial and Operational Security: In international trade, especially transactions involving a Letter of Credit (L/C), an SGS report is often a mandatory document required by banks to release payment. It provides all parties with the security that the terms of the contract have been met.

Kaolin.om’s Commitment to Transparency

At Kaolin.om, we believe that trust is built on transparency. We proactively engage SGS to verify our metallurgical products because we are confident in the quality of the materials we supply. All our Iron Ore, Iron Pellets, and Chrome Ore products are supported by SGS inspection reports.

We don’t just tell you our products are high-quality; we provide the independent proof.

To learn more about our quality assurance process or to review an SGS report for one of our products, contact our team today.