When procurement managers and metallurgists evaluate iron ore pellets, the first metric they often look at is the total iron (Fe) content. While a high Fe content is undoubtedly crucial, it only tells part of the story. For an efficient and cost-effective steelmaking operation, the mechanical strength of the pellet is arguably just as critical.

The primary measure of this strength is a metric known as Cold Crushing Strength, or CCS. This article explains what CCS is, why it is so vital for furnace performance, and what constitutes a high-quality value.

What is Cold Crushing Strength (CCS)?

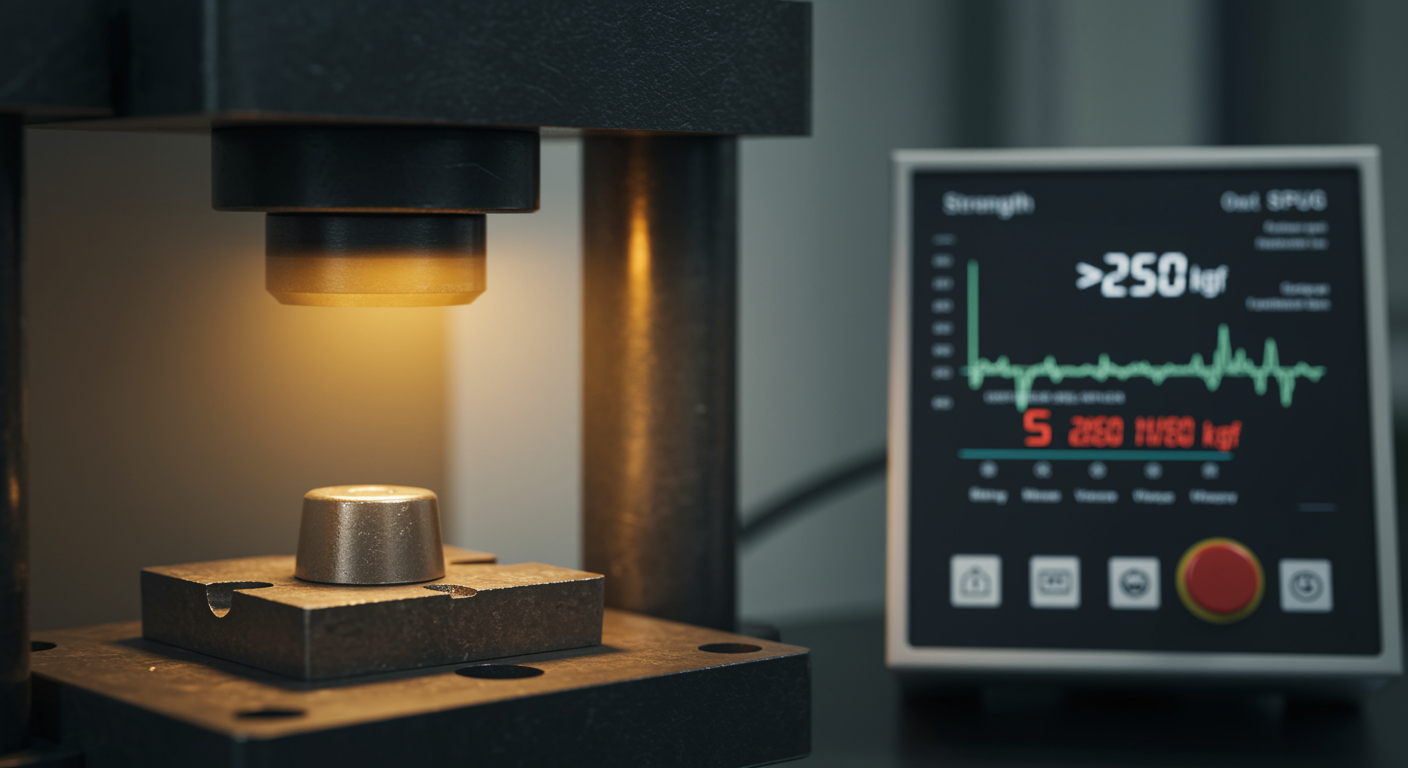

In simple terms, Cold Crushing Strength is a measure of how resistant a fired iron ore pellet is to being crushed. The test is straightforward: a single pellet is placed between two flat plates, and pressure is applied until the pellet breaks. The amount of force required to crush it, typically measured in kilograms-force per pellet (kgf/p), is its CCS value. An average is taken from a sample of multiple pellets to determine the overall CCS for a given batch.

The Journey of a Pellet: Why Strength is Essential

To understand why this metric is so important, consider the long and arduous journey a pellet takes before it is finally converted into steel:

- It is produced and handled at the pelletizing plant.

- It is loaded, transported (often by ship and rail), and unloaded multiple times.

- It is stored in large stockpiles, where it endures immense pressure from the pellets above it.

- Finally, it is loaded into the top of a blast furnace, dropping into a massive column of other raw materials.

A pellet with low CCS will not survive this journey intact. It will break, chip, and crumble, creating excessive amounts of “fines” (iron ore dust).

The Tangible Business Benefits of High CCS

The generation of fines is a major problem for any steel plant. Strong pellets with high CCS values provide direct, measurable benefits:

- Maximized Furnace Efficiency: Strong pellets maintain their shape inside the furnace, ensuring good permeability. This allows hot reducing gases to flow freely and evenly through the raw material burden, leading to more efficient heat transfer and lower fuel (coke) consumption.

- Reduced Material Waste: When weak pellets degrade into dust during transport and handling, that is valuable iron-bearing material being lost. High CCS means you get to use more of the product you paid for.

- Increased Productivity and Stability: Fines can choke a blast furnace, reducing permeability and causing operational instability (known as “hanging” or “slipping”). A stable, permeable burden allows the furnace to run smoothly at higher production rates.

The Kaolin.om Standard: What is a Good CCS Value?

For modern blast furnace operations, a CCS value above 200-220 kgf/p is generally considered good. However, premium pellets offer an even greater margin of performance and reliability.

At Kaolin.om, we understand that our clients’ efficiency depends on the mechanical integrity of our products. That is why we supply premium iron pellets with an excellent average Cold Crushing Strength of over 250 kgf/p, as verified by SGS inspection.

This isn’t just a number on a data sheet; it’s our guarantee of superior performance, reduced waste, and a more efficient steelmaking process for your plant.

Don’t let pellet degradation impact your bottom line. Contact our technical team today to receive the full specifications for our high-strength iron pellets.